Corespec > Sustainability

As an Environmentally aware business we have worked hard over the years to reduce our Carbon footprint with various projects. This has resulted in the following –

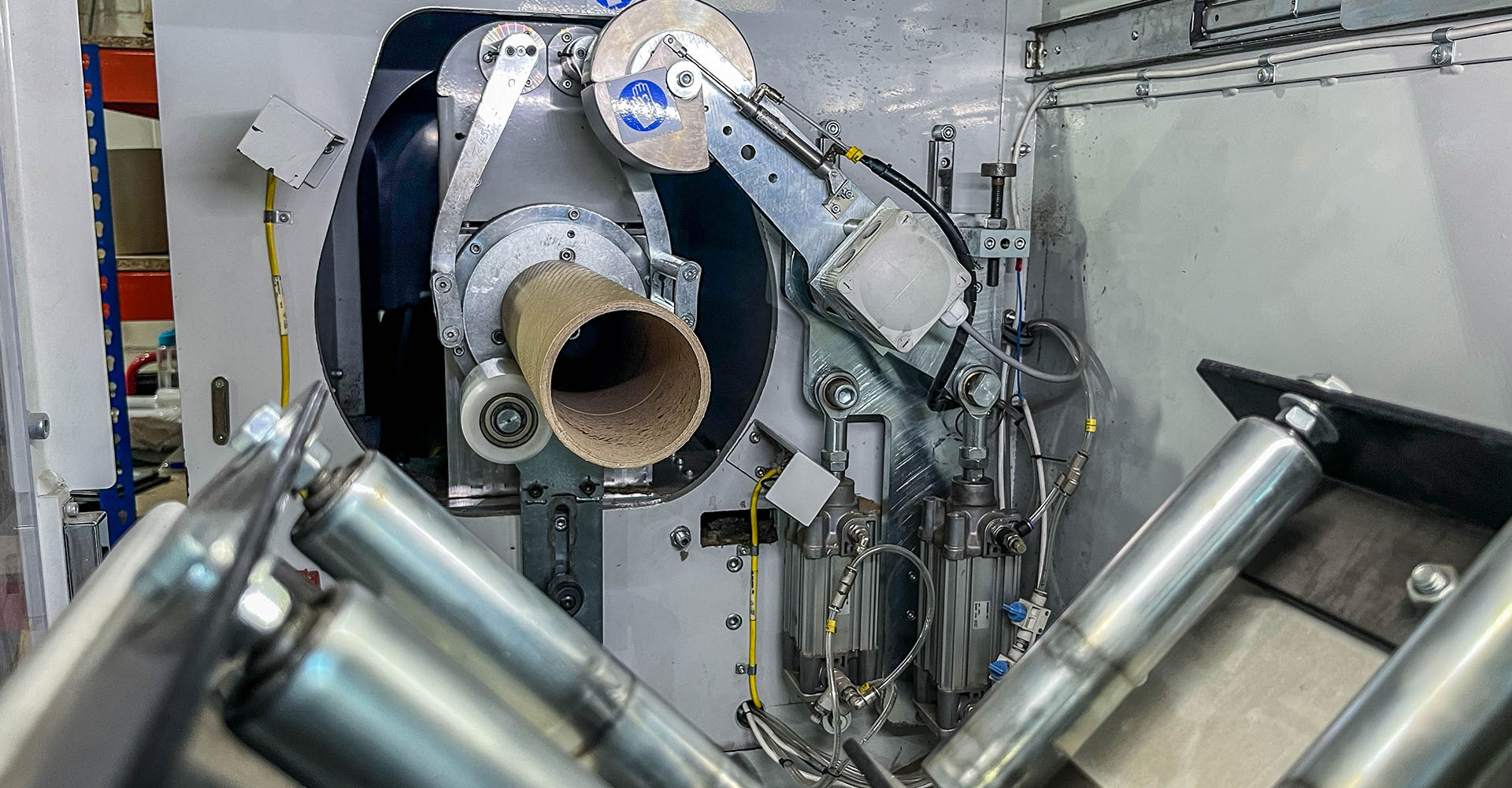

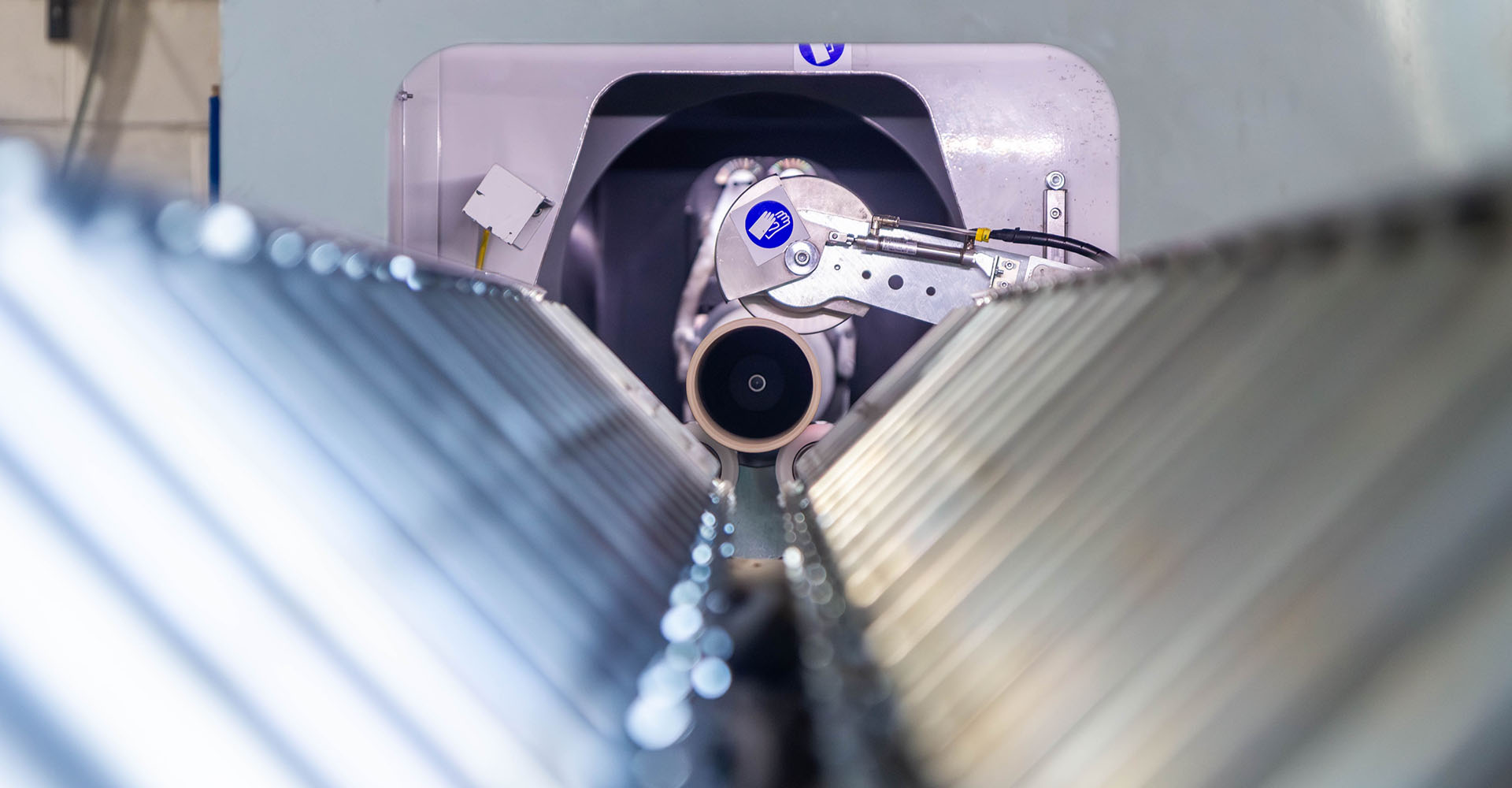

- All our cores are manufactured only using recycled core board. All our coreboard suppliers are FSC certified and all subject to U.K / E.U laws and regulations on sustainability and the environment

- Our Lean Manufacturing techniques have focused on maximising efficiencies and reducing waste which has resulted in streamlined processing and significantly decreased the amount of scrap production, saving on raw materials, time and energy.

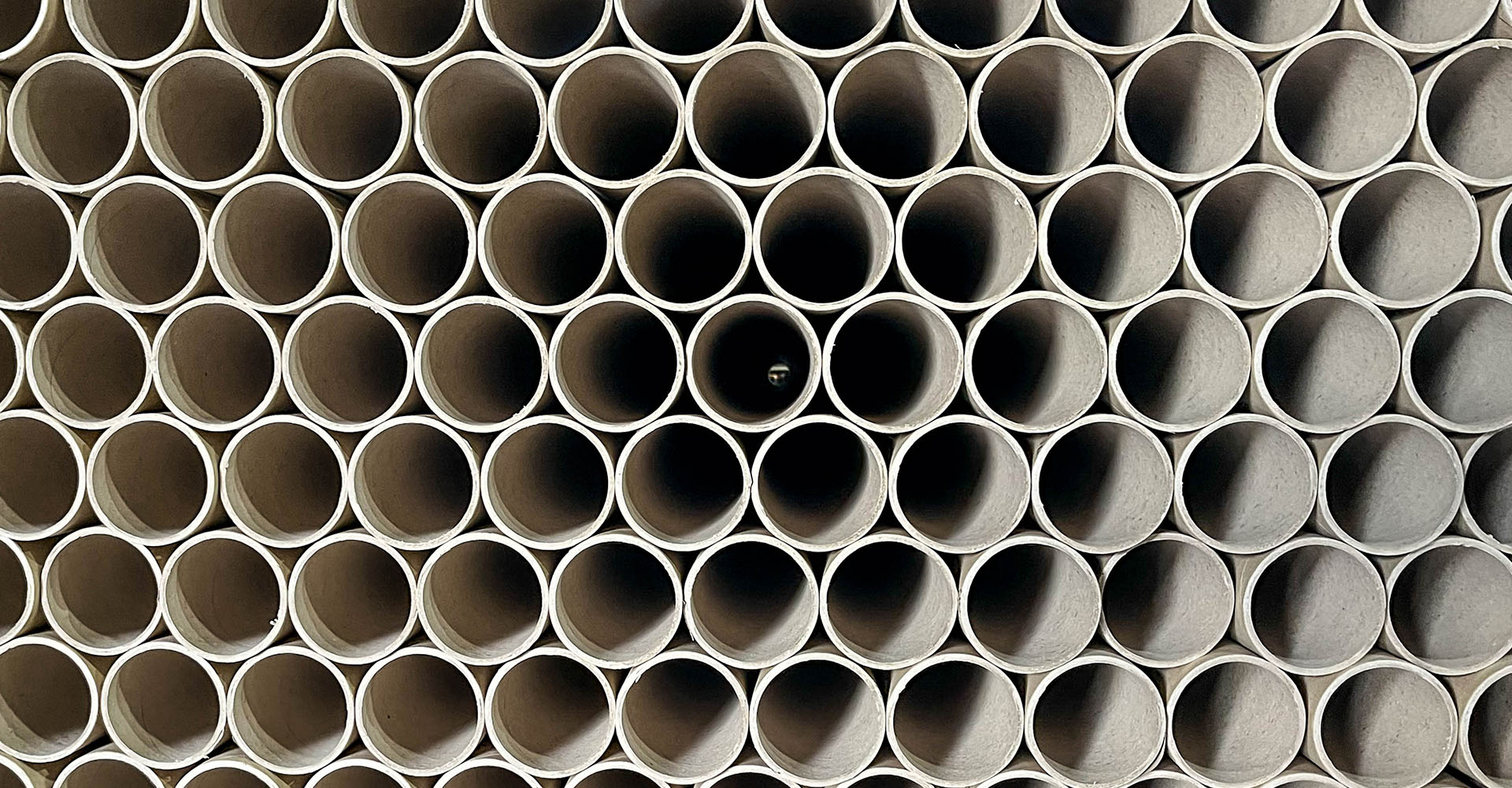

- All our cores can be fully recycled at the end of their usable life

- All our internal waste coreboard is fully recycled

- Any other recyclable waste is separated and stored separately to be recycled by nationally recognised waste companies on an ongoing basis to ensure that nothing that can be recycled ends up going to landfill

- A reduction in the amount of plastic used in the packaging of our products. The company only purchases plastic strapping / stretch wrap that has been manufactured utilising recycled content

- Transport maximisation by ordering full loads of raw materials and careful planning of our outgoing loads to ensure trucks are as close to capacity as possible and customer deliveries are planned in the same area to reduce the number of trucks needing to be loaded and reduce the actual mileage

- Our fleet of Fork Lift Trucks are now fully electric with quick charging batteries

- All factory and warehouse lighting has been changed to LED

- A shift in mindset that although we’re always happy to meet a customer, supplier or a representative of a support business in person, we would encourage an on-line meeting in the first instance to reduce the amount of time a vehicle is on the road over a year.